The main objective of the MarTEnergy research was to develop a highly efficient half-Heusler (HH) based prototype thermoelectric converter, covering most of the potential practical applications conditions, including maritime gasoline engines. Thermoelectric is one of the emerging technologies for effective recovery of waste heat and consequently its conversion into useful electricity. Thermoelectric generators can be used in a wide variety of applications including electricity generation in extreme environments, waste heat recovery in transport and industry, domestic production in developing and developed countries, micro-generation for sensors and microelectronics and solar thermoelectric generators. The fact that thermoelectric generators have no moving parts, require no maintenance, have inherently high reliability and long service-free lifetimes, makes them well suited for equipment with low to modest power needs in remote uninhabited or inaccessible locations such as mountaintops, the vacuum of space, or the deep ocean. This will contribute greatly to enhancing energy efficiency and reducing global reliance on fossil fuels, reducing greenhouse gas emissions, and promoting sustainable development.

Various researchers have developed novel highly efficient thermoelectric materials, yielding conversion efficiencies of more than 11%, mainly by using advanced nano-structuring approaches for the reduction of lattice thermal conductivity. Nevertheless, although well-established TE electrical power generation applications are operative since 1950, such applications still involve TE alloys containing scarce (e.g. Te), expensive (e.g. Ge) and environmentally unfriendly (e.g. Pb) raw elements, in addition to having still limited (~6%) efficiencies. Overcoming the barriers associated with development of such practical TE converters, requires the combined efforts of thermoelectric materials development experts and practical conversion devices' designers. Furthermore, in the maritime shipping industry, there is actually a huge loss of wasted heat as well as high level of CO2 emissions. In such industry, it is critical to integrate new technological knowledge to recover waste energy, increase the energy efficiency, and decrease CO2 emissions.

Overall, the achievements of the MarTEnergy project were:

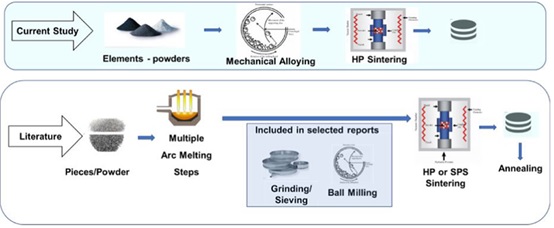

- Thermoelectric half Heusler materials have been successfully synthesized using various techniques (mechanical alloying, arc melting, flux method). Among these techniques, mechanical alloying was selected as the most advantageous based on practical considerations as well as thermoelectric performance. Half Heusler compositions were optimized and all studies were based on complementary techniques (XRD, SEM/EDX, TEM, TE measurements). Maximum achieved ZTs were 1.1 for p-type and 0.7 for n-type members.

- Prototype module based on half Heusler materials has been developed. Work on the design of the module using finite element analysis, the development of the metallic contacts, setting up the prototype and its characterization has been carried out. The prototype was tested at a hot side temperature of 500oC.

- Simulations regarding the applications in maritime were carried out to explore the potential of converting waste heat from ships to electricity with TEG. End-users conditions were set in collaboration with Synergy Group as well as Columbia Shipmanagement. Several cases on different possible positions for the generator have been proposed and studied. Cost benefit analysis as well as life cycle analysis were also done to include all aspects of such applications.

Overall, MarTEnergy project combined research at different aspects of thermoelectrics: optimizing materials and methods, design and development of modules and simulations for application in maritime sector. MarTEnergy project showed high performance for HH prepared with simple and scalable method as well as their potential for maritime applications. The results were presented in various conferences and published in scientific journals (more info at the dissemination page).